Seven Challenges LED lights Designers Face

27-03-2014Do LED lights always disappoint manufacturers label claims in real-life applications? Not all the time, according to James Wallace, Principal and Design Director of Light Plan and Director of the Professional Lighting Designers Association (PLDA).

Speaking at a presentation at 2014 Taiwan Solid State Lighting Forum organized by Industrial Technology Research Institute at Taipei World Trade Center Nangang Exhibition Hall on March 20, 2014, Wallace mentioned seven problems LED lights designers still face .

Topping LED lights designers list of the biggest challenges of using LEDs was glare with overwhelming 47 percent respondents in a PLDA survey reporting a need for glare reduction. This was followed by ease of dimming; interchangeable components; better heat dissipation management; standardized color and data presentation; as well as lower costs.

1) LED glare and shadowing

On the design side, strong glare and shadowing can be problematic. An issue that manufacturers responded can be fixed by switching from Device On Board (DoB) to Chip on Board (COB). Wallace estimated future lighting trends will include the gradual replacement of SMT to COB to reduce shadowing.

2) LED dimming not as smooth as claimed

However, the most surprising complaint from the LED lights design community has been the dimmable capabilities that the LED industry prides itself in actually do not dim smoothly. Wallace said dimmable LEDs dim in steps does not appear smoothly compared to conventional lighting, and do not always perform according to expectations. Aside for dimmable properties, LED color tuning technologies should also be adjustable. Different cultures have different color temperature preferences, the Japanese for example prefer a cooler white. Clients also might prefer tunable colors for different seasons, such as cooler color temperatures for summer and warmer color temperatures for winter.

3) Lack of color and measurement standardization

Lack of LED industry standards for Color Correlated Temperature (CCT) and data presentation also continue to trouble designers, when it comes to picking the right bulbs for projects. If the labels are misleading, lighting designers might end up with legal responsibilities, a fine, and a damaged reputation. The task of picking the right bulb appears difficult though, as color temperature labeling tends to vary from manufacturer to manufacturer, even when labels may show the same CCT range the colors can be completely different. Manufacturers have responded to PLDA that this can be overcome if the industry only makes three types of color temperature bulbs: 2,700K, 4,000K 6,500K.

The CRI of LED lights are also known in the design industry to change color under temperature changes. Sometimes the change is so big and noticeable that it becomes rather uncomfortable. Manufacturers have told designers that color changes are always a result of changing CRI, and due to lighting limitations it may be difficult to maintain color temperature.

Designers also face difficulties in arranging lighting label measurements as manufacturers use different standars and measurement criteria. Wallace also pointed out there is currently no design tool for LEDs and it may take another four to five years to develop one.

4) Thermal management

The good news for designers is manufacturers are increasingly able to control heat dissipation as LED efficacy improves. Higher efficiency has resulted in less heat loss, and make products better suited for hot climate applications. Technological advancements have enabled innovations in LEDs that now enable heat sink free bulbs.

5) Interchangeability

Clients expect long lifetimes for LED lights that tend to last at least 30 years, making component interchangeability increasingly important. Although, Zhaga has taken steps in introducing interchangeable lights into the industry, it is not enough, said Wallace. The Australian designer noted Zhaga specifications are designed from manufacturer perspective, but not from the end-user’s perspective of interchangeability.

6) Need for lower costs

The shift of clients using LED has been geat due to lowered costs. Yet, costs still remain as a barrier to introduce clients to the new technology. "LED lights designers have to fight onto manufacturers behalf to get price on, if it is above 30 percent than it is difficult to get it through," said Wallace. The trouble for manufacturers is a balance between costs and product functionality. While costs may depend on the complexity of the project and whether it includes color tunable features, a premium cost of above 30 percent for immersive lighting projects can be difficult to justify to clients, explained Wallace.

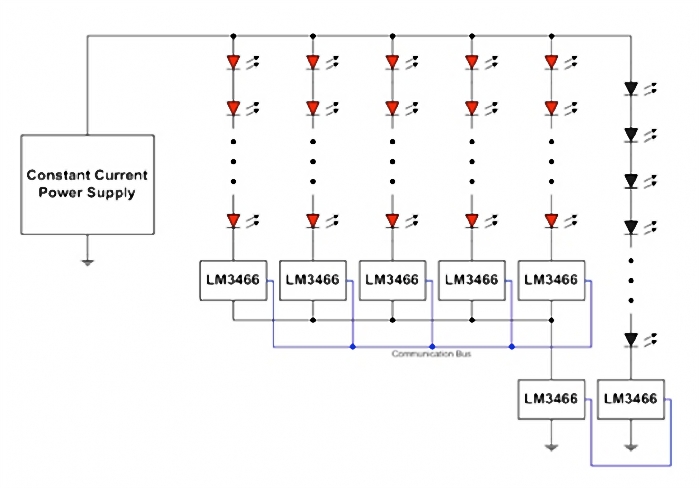

Wallace forcasted in the future more effort will be put into increasing glare control in outdoor lighting. Manufacturers that first launch products with ease of dimming and acceptable solutions, greater interchangeability, will benefit from added value. In addition, LED lights drivers will be designed to accept common coommunication protocol DALI DMX 512-10 volt, Switch-dim and others. Lastly, Zhaga should be broadened to include end-users need for interchangeability. Perhaps when all these conditions are met, designers will finally be able to pick "the right light at the right time at the right place."