Cree LED chips can provide more lumen for LED lights designers

29-03-2014Characterization tools offered by LED chips manufacturers such as Cree can help the design team weight the balance, especially in terms of efficacy.

Product Characterization Tool (PCT) shows that Crees brightest cool-white, single-die LED components tested at a reasonable operating temperature of 55°C are all capable of delivering component efficacy well above 100 lm/W at elevated drive currents. Similarly with warmer phosphor mixtures, Cree’s brightest warm-white, single-die LED components deliver 75-90 lm/W at 55°C, at

drive currents well above the binning current.

LED chips manufacturers, who provide engineering tools to perform system analyses, allow for rapid, basic performance assessment. When long-term performance and reliability data are available over a wide range of operating conditions, device and component-level non-linearities need not be important selection criteria. They are simply attributes of the devices to be taken into consideration during the design cycle. Long-term performance data at elevated currents and temperatures allows an assessment of whether there is a valid concern for a particular manufacturer’s particular LED chip under consideration.

While weve shown that driving LEDs at higher drive currents and/or elevated temperatures allows the designer to get more lumens from each LED, there are practical restrictions. The LED lights designer must consider issues such as thermal system design when looking to reduce LED component count and thereby also reducing costs. The following examples illustrate the system considerations.

System restrictions

Crees XLamp MT-G EasyWhite LED is a multi-die LED, optimized for high-output, small-form-factor, directional lighting applications. The maximum current rating for the MT-G is 4000 mA, a substantial 24W in a 9×9-mm package. But a small-form bulb, such as an MR16, cannot dissipate greater than 20W of thermal load. The following figure expresses the LED alone and designed into an MR16 lamp design.

Based on Crees experience in building a MR16 reference design we found that heat sinks for the MR16-class LED sources could safely cool down 4-7W of power. The geometry of the heat sink restricts the drive capacity of the LED system. The above figure shows that, in the case of an MR16 lamp, the LED must be driven relatively close to the binning current and far below the maximum drive current. The MT-G LED, when used with a larger heat sink – such as a heat sink to support a PAR38 bulb application with several times the mass of the MR16 heat sink – can support a much higher drive current.

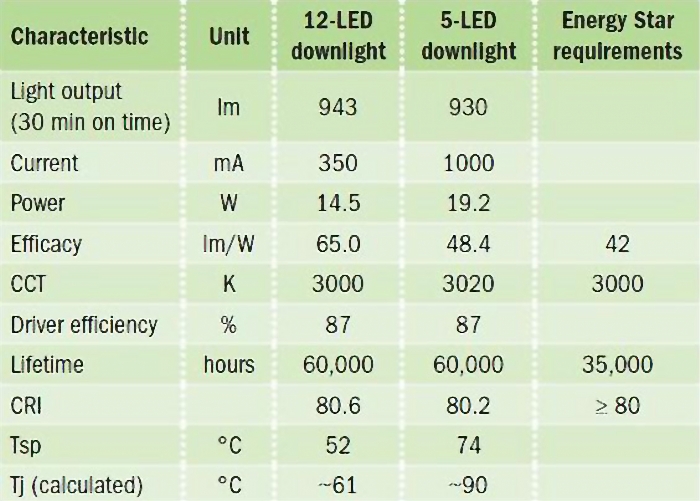

Crees Shenzhen Technology Center has developed other reference designs that illustrate the concept of LED operating capacity tradeoffs. Engineers built two 6-inch recessed downlight fixtures using Crees XLamp XP-G LED. Using the same mechanical enclosure and heat sink, but different drivers and numbers of LEDs, we developed two systems with nearly identical light output, distribution, CCT and CRI. One design uses 12 XP-G LEDs being driven at the LED’s 350 mA binning current while the other uses 5 XP-G LEDs driven at 1000 mA.

The above table summarizes the results. Though differing in efficacy, both downlights meet Energy Star efficacy, matched color temperature (CCT) and color rendering index (CRI) requirements. In this example one can reduce the number of LEDs in a fixture by 60%, obtaining almost identical optical performance in exchange for a high, but still reasonable, operating temperature and reduction in system efficacy.

Note that in some cases Energy Star requirements can also limit the choice of drive currents. Efficacy is a key element in Energy Star and at some point a higher drive current in a particular system design could result in an efficacy spec below the Energy Star limits.

Generally, however, LED lights have far more lighting capacity than most designers are using. The highest quality LED chips are capable of operating at continuous, elevated currents and temperatures far above manufacturers lighting class information. New lights and lamp designs should take advantage of these attributes. For lighting class LEDs, there is no reliability penalty for using more of this capacity.