Heat Dissipation Management Is Vital To The Lifetime of LED Lights,Especially For Offroad LED Light

29-07-2015The LED industry is one of the fastest growing industry. Despite LEDs being used in many electronic devices for many years, more recent developments in high-power LEDs have led to many ranks of LED use in all types of LED lights, automotive (Fig. 1), signage, and domestic appliance products. LED lights can be very reliable, but that reliability depends on excellent thermal design around the component. This article will describe how careful selection of thermal materials - along with an understanding of how the material is used - is a requirement for top-performing and long-life LED lights.

In offering replacements to halogen, incandescent, and fluorescent lighting systems for both interior and exterior applications, the growth of the LED light market will be huge. For example, Strategies Unlimited predicts that the total market for LED lights will grow from $59B (billion) in 2014 to $66B in 2022. But penetration of LED units will rise from around 30% to almost 70% over that same period. The growth arises from the advantages LEDs offer over traditional lighting forms in terms of adaptability, lifetime, and efficiency. LED lights allow more design freedom, offer an exceptionally long lifetime, and are also much more efficient - converting much energy to light and thus minimizing the heat given off.

|

|

FIG. 1. Applications such as LED headlights in automobiles can require superior thermal mitigation for reliable operation along with protection of the LED from the elements. |

Heat at the junction

LED lights, however, do still produce much heat at the semiconductor junction. This heat can have an bad influence on the LED chips and therefore must be managed to ensure that the true benefits of LED lights are realized. Typically categorized by color temperature, LED lights are available in many color variants.

With a change in operating temperature of the LED lights, a change will also occur to the color temperature. For example, with white light an increase in temperature could lead to a warmer CCT coming from the LED. In addition, if a variance in die temperatures is present across LEDs in the same array, a range of color temperatures may be emitted, thus affecting the quality and housing appearance of the end lighting product.

As shown in Table 1, maintaining the correct die temperature of the LED can not only extend the working life but also lead to more light being produced; therefore, fewer LED chips may be needed to achieve the desired effect. An increase in operating temperature can have a bad but perhaps recoverable effect on the properties of the LED light. However, if excessive junction temperatures are reached, particularly above the maximum operating temperature of the LED (~120-150°C), a non-recoverable effect could occur, leading to complete failure.

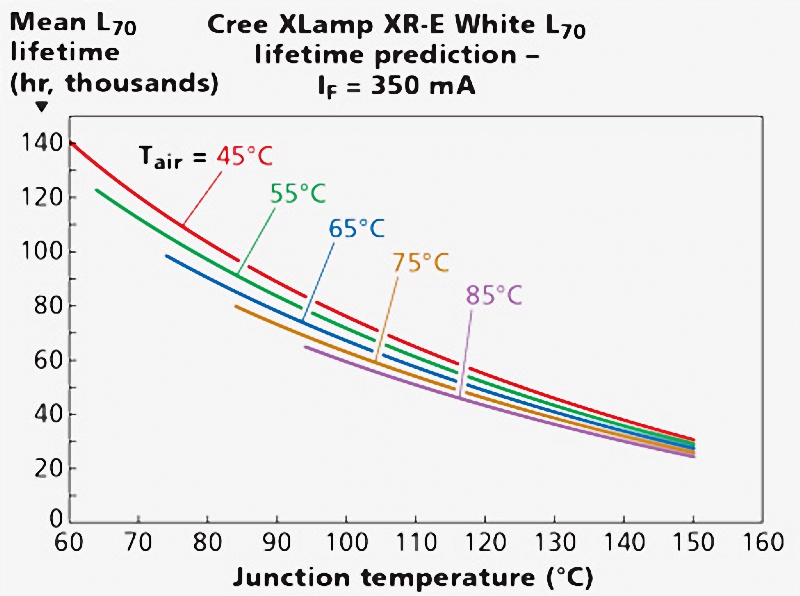

Indeed, operating temperature is directly related to the lifetime of the LED; the higher the temperature, the shorter the LED life as shown in Fig. 2. The same theory is also true for the LED driver ics where the lifetime of the driver ic can be calcualted from the lifetime of the electrolytic capacitor; by calculation it can be determined that for every 10°C drop in the operating temperature the lifetime of the capacitor is doubled. Ensuring efficient thermal management is used will therefore provide reliable quality, appearance, and longer lifetime of LED lights, and in turn, creates the opportunity for further applications for this ever-evolving industry.

Thermal mitigation

There are many methods to improve upon the thermal management of LED lights, and the correct type of thermally conductive material must be chosen in order to ensure the desired results for heat cooling are achieved. In the area of materials, products range from thermally conductive encapsulation resins, offering both heat dissipation and environmental protection, to thermal interface materials used to improve the efficiency of heat conduction away from the LED junction.

|

|

FIG. 2. The curves document Cree XLamp LED lifetime relative to junction temperature with the LEDs driven at 350 mA. |

Thermal interface materials are components designed to fill the gap between the device and the heat sink and thus reduce the thermal resistance at the boundary between the two. Such a material leads to faster heat loss and a lower operating temperature for the device. Curing products can also be used as bonding materials. Solutions include silicone RTV (room temperature vulcanization) or epoxy compounds - the choice will often depend on the bond strength or operating temperature range required.

Another option for managing the transfer of heat away from electronic devices is to introduce a thermally conductive encapsulation resin. These products are designed to offer protection of the unit from environmental attack while also allowing heat generated within the device to be cooled to its surroundings. In this case, the encapsulation resin becomes the heat sink and conducts thermal energy away from the device. Such products can be used to encapsulate the technology behind and attached to the LED device and can also assist with light cooling from within the unit, depending on the color chosen.

Encapsulation resins also cover the use of thermally conductive fillers; however, the base resin, hardener, and other additives used can be changed to provide a wide range of solutions, including epoxy, polyurethane, and silicone chemistries. The different chemistry solutios will provide a range of properties and each should be considered depending on the end applications.

Encapsulation material solutions

For example, a polyurethane material offers excellent flexibility, particularly at low temperatures, a major advantage over an epoxy system. A silicone resin can also suit this flexibility at low temperatures as well as offering superior high-temperature performance, well more other chemistries available. The silicone products are also typically more expensive.

TABLE 1. LED performance varies with temperature, as shown in characterization of a Cree XLamp LED

|

Temperature (°C) |

Luminous flux (lm) |

Voltage (V) |

Efficacy (lm/V) |

|

25 |

196.1 |

3.237 |

86.5 |

|

60 |

182.2 |

3.149 |

82.7 |

|

85 |

172.3 |

3.087 |

79.7 |

Epoxy systems are very tough and offer excellent protection in a variety of harsh and offroadenvironments. They are hard materials with low coefficients of thermal expansion and, in some cases, a degree of flexibility can be combined into the product. The formulation of encapsulation resins can lead to a vast array of products with tailored properties for single applications; therefore, it is advised that applications are discussed in detail with a relevant material supplier.

Application properties

Regardless of the type of thermal management product chosen, there are many key properties that must also be considered. These can be quite simple parameters, such as the operating temperatures of the device, the electronic index, or any processing constraints such as viscosity, cure time, etc.

Other parameters are more important to the device and a value alone may not be enough to describe the correct product. Thermal conductivity is a primary example. Measured in W/m•K (watts per meter kelvin), thermal conductivity represents a materials ability to transfer heat. Bulk thermal conductivity values, found on most product datasheets, shows well the level of heat transfer expected, allowing for comparison between different materials.

Relying on bulk thermal conductivity values alone, however, will not necessarily result in the most efficient heat transfer.

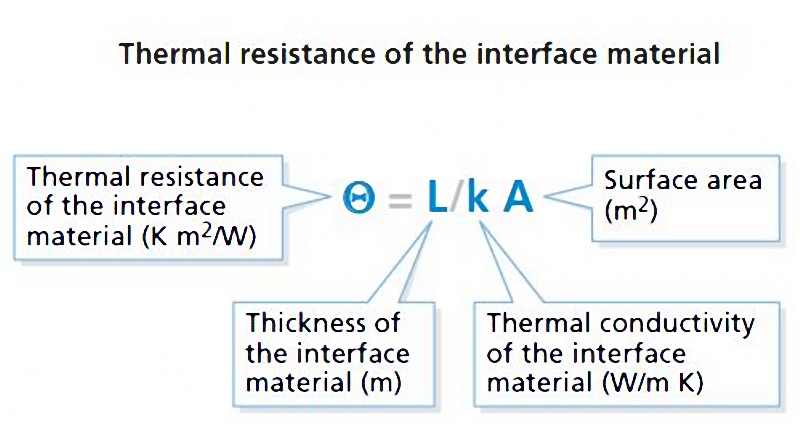

Thermal resistance, measured in K•m2/W, is the reciprocal of thermal conductivity. It considers the interfacial thickness. Although the metric is dependent on the contact surfaces and pressures used, some general rules can be followed to ensure thermal resistance values are kept to a lowest value, thereby maximizing the efficiency of heat transfer.

|

|

FIG. 3. Understanding the thermal resistance formula is necessary in selecting optimum thermal materials. |

For example, a metal heat sink will have a significantly higher thermal conductivity than a heat transfer compound used at the interface, so it is important that only a thin layer of this compound is used. Increasing thickness will only increase the thermal resistance in this case. Using the formula in Fig. 3, some basic calculations can provide some examples of the differences in thermal resistance likely to be seen between a thermal paste applied at 50 μm and a thermal pad that is 0.5-mm thick. Therefore, lower interfacial thicknesses and higher thermal conductivities give the greatest improvement in heat cooling.

Caution with test methods

There is, however, a consideration with using bulk thermal conductivity values alone or comparing thermal resistance values given on the product datasheets. Great variations in thermal conductivity and thermal resistance values for the same product can be achieved by utilizing different test methods or parameters. Such variation can result in bulk thermal conductivity values that appear very high when quoted but in use have a dramatically reduced efficiency of heat dissipation. Some methods only measure the sum of the materials thermal resistance and the material/instrument contact resistance. Electrolube uses a version of the heat-flow method that measures both of these values separately, giving a much more accurate bulk thermal-conductivity measurement.

The test for thermal resistance should ideally be made on the actual unit using the normal application, spacing, and weight/pressure parameters or alternatively using a comparable method where the pressure is described. However these tests may be made, it is necessary that products are compared using the same method to obtain bulk conductivity and thermal resistance values; in all cases, the products should be tested in the final application for a true reflection of effective heat dissipation.

Application theory

This idea leads us to another important factor in product selection - the application of thermal management materials. Whether it is an encapsulation component or an interface material, any gaps in the thermally conductive contact will result in a reduction in the rate of heat dissipation.

For thermally conductive encapsulation resins, the key to success is to ensure the resin can flow all around the unit, including into any small gaps. Such uniform flow helps to remove any air gaps and ensure there are no pockets of heat created throughout the unit. In order to achieve such application, the resin will need the correct combination of thermal conductivity and viscosity.

Typically, as the thermal conductivity of resins increases, the viscosity also increases. Electrolube offer specialist resins to help reduce viscosity for ease of application while maintaining a high level of thermal conductivity for efficient heat dissipation.

TABLE 2. Thermal interface material characteristics directly impact LED device temperature, as documented for a Cree XLamp LED.

|

Product no. |

Bulk thermal conductivity (W/mxK) |

Device temperature (°C) |

Reduction in temperature (°C by %) |

|

No interface |

N/A |

30 |

N/A |

|

1 |

12.5 |

22 |

27 |

|

2 |

1.0 |

24 |

20 |

|

3 |

1.4 |

21 |

30 |

|

4 |

4.0 |

23 |

23 |

For interface materials, the viscosity of a product or the minimum thickness possible for application will have a great influence on the thermal resistance. Therefore, a highly-thermally-conductive, high-viscosity component that cannot be evenly scattered onto the surface may have a higher thermal resistance and lower efficiency of heat dissipation when compared to a lower-viscosity product with a lower-bulk-thermal-conductivity value. It is necessary that users tell bulk thermal conductivity values, contact resistance, application thicknesses, and processes in order to successfully achieve the best in heat transfer efficiency.

A practical example strengthening the requirement for such considerations is provided in Table 2. The data shows the potential differences in heat dissipation by measuring the temperature of a heat-generating device in use. These results have been based on work completed by an end user, where all products were thermal interface components, applied using the same method at the same thickness.

It clearly shows from the table that a higher-bulk-thermal-conductivity value, in this case 12.5 W/m•K, does not necessarily result in more effective heat dissipation when compared to products with lower values, such as the 1.4 W/m•K option. The reason for this fact could arise from the processing method not being suitable for the product, the product not being easy to apply, or possibly the product was not designed for this particular application and thus is showing a high thermal resistance when compared to the other products tested. Whatever the reason, it highlights the importance of product application as well as product selection; by finding the correct balance of both of these parameters, the highest efficiency of heat transfer can be achieved.

Looking back at the original data for LED performance versus lifetime in Fig. 2, and using the previous results as an example, a conclusion on the importance of the use and correct selection of thermal management materials can be made. Take product #2 from Table 2. This choice reduces the operating temperature by 20% in the tested application. If a similar percentage reduction was achieved for the LED lights discussed, it would result in increased efficacy through the reduction in operating temperature from 85°C to 68°C, and similarly, an increased lifetime from 95,000 hours to 120,000 hours - a big improvement.

But, when you compare the prior specification to product #4 in Table 2, a greater operating temperature reduction is achieved, resulting in an increase in efficacy greater than 3% and an increased lifetime from 95,000 hours to 140,000 hours. Therefore, by selecting the correct product and using the best process, lifetime can be improved by a further 15-20% when using product #4 in place of product #2.

With such rapid improvements in the electronics industry, and more specifically in LED applications, it is a must that materials technology is also introduced to meet the ever-demanding requirements for heat dissipation. Electrolube has improved specific technologies to improve the ability to process thermal management components easily and effectively. This has resulted in reduced viscosity compounds with higher bulk thermal conductivities; with these two properties combined, these products provide highest efficiency in heat dissipation by minimizing thermal resistance.

The technology has now also been introduced to encapsulation compounds, providing products with higher filler loadings and thus improved thermal conductivity combined with improved flow. In addition and to be discussed in Part II of this article, Electrolube also produces a range of products other than thermal management materials. Such products include conformal coatings and encapsulation resins in optically clear formats for applications where protection of the entire LED is required, once again confirming the importance of continually developing formulated chemical products to meet the strictest requirements of this technology.