USA scientists have found better solution to make green LEDs brighter and more energy-saving

06-08-2016Scientists at the University of Illinois in USA have developed a new solution for making brighter and more efficient green color LED chips. Using an industry-standard semiconductor growth technology, they have created gallium nitride (GaN) cubic crystals grown on a silicon substrate that are able to make powerful green LEDs for advanced LED lighting.

This project is very revolutionary as it is ready for the latest green wavelength emitters that can target advanced LED lighting on a scalable CMOS-silicon platform by exploiting the new cubic gallium nitride.

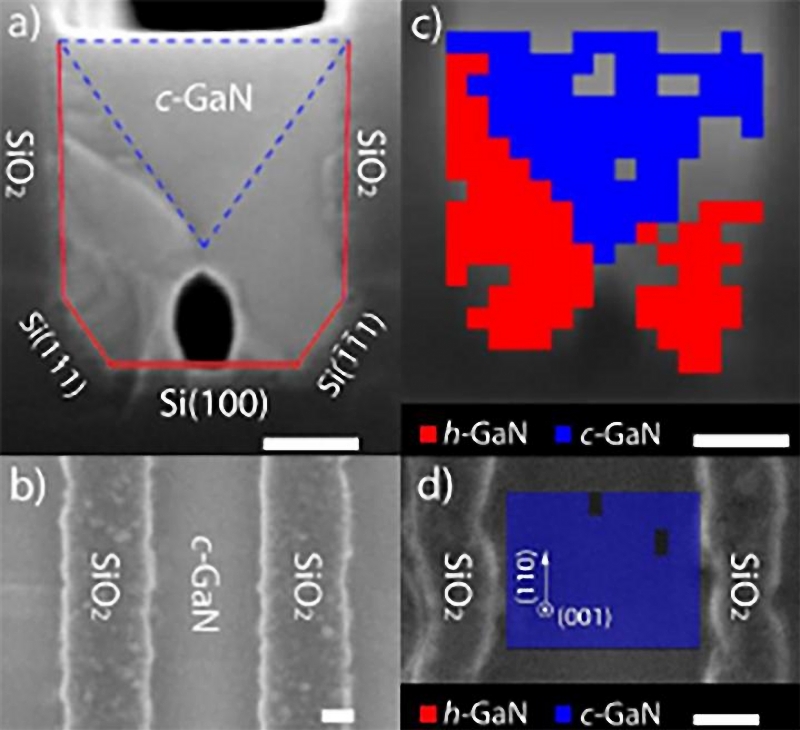

A new method of cubic phase synthesis: Hexagonal-to-cubic phase transformation. The scale bars represent 100 nm in all images. (a) Cross sectional and (b) Top-view SEM images of cubic GaN grown on U-grooved Si(100). (c) Cross sectional and (d) Top-view EBSD images of cubic GaN grown on U-grooved Si(100), showing cubic GaN in blue, and hexagonal GaN in red.

The combination of LED lighting with sensing (e.g. detection) and networking (e.g. communication) to enable smart (i.e. responsive and adaptive) visible lighting, is further aimed to revolutionize the way we are using LED light. And CMOS-compatible LEDs can achieve fast, efficient, low-power, and multi-functional technology solutions with less of a footprint and at an ever more affordable device price point for these applications.

Basically, GaN forms in one of two crystal structures: hexagonal or cubic. Hexagonal GaN is thermodynamically stable and is by far the more conventional form of the semiconductor. However, hexagonal GaN is easy to a cause a phenomenon known as polarization, where an internal electric field separates the negatively charged electrons and positively charged holes, preventing them from combining, which finally lowers the light output efficiency.

So far, the only way scientists were able to make cubic GaN was to use molecular beam epitaxy, a very expensive and slow crystal growth method when compared to the widely used metal-organic chemical vapor deposition (MOCVD) method .

Having better performing green LEDs will make a new market for LED in general LED lighting. For example, these LED lights will provide energy savings by generating white light through a color mixing approach. Other advanced applications include ultra-parallel LED connectivity through phosphor-free green LEDs, underwater communications, and biotechnology such as optogenetics and migraine treatment.

Enhanced green LEDs aren the only application, which could someday replace silicon to make power electronic devices found in laptop power adapters and electronic substations, and it could replace mercury lamps to make ultra-violet LEDs that disinfect water.