NEWS

NEWS

Micro LED sees new business opportunity in foldable and flexible applications

06-10-2019

Innovative display technology is not a new idea when more and more Micro/Mini LED display products shown at important international events in the past two years.

However, we still see several challenging problems in Micro LED and Mini LED production process that hinder its commercialization. so, more industry players are expected to join the market, which will help to develop solutions for technology improvements.

From the beginning of 2019, more and more companies announced their Micro LED products and their relevant patents. Some companies used PCB backplane for large size signage while many panel suppliers produced Micro LED products on glass backplanes. But the biggest size of Micro LED display module falls at 12 inches due to low yield. Basically speaking, larger sized panels are manufactured by splicing the small ones.

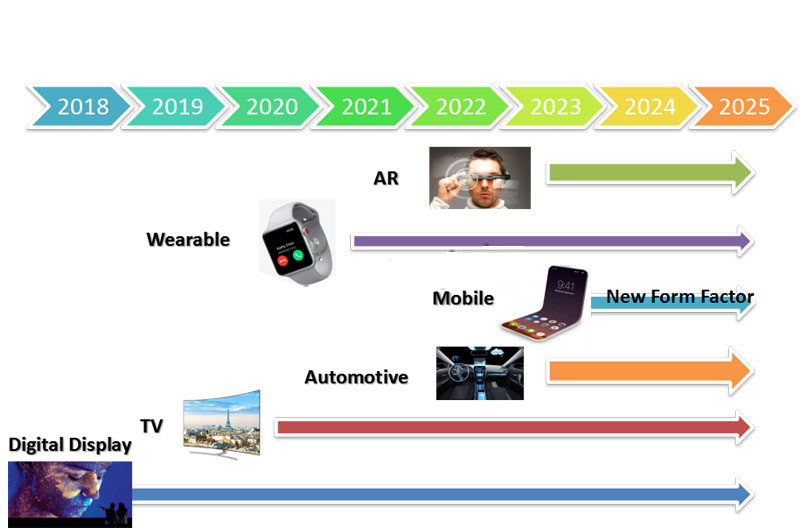

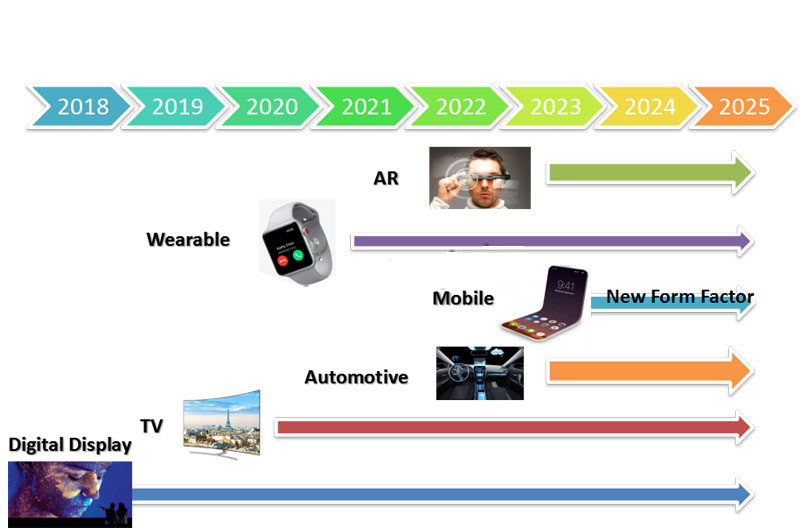

On the other hand, smaller sized displays usually use Si-CMOS backplane solutions whose companies from the U.S. and Europe take the lead. Apple, Facebook and Google are all working on wearable devices and AR/VR applications with Micro LEDs. Specification of related products is up to high ppi resolution with Micro LED on Si-CMOS backplane. While achieving high brightness, these products still face challenges of delivering high resolution with full color.

In the high performance display market, Micro LED only has chances for applications aiming at larger sized (above 65-inch) displays when it achieves a higher yield of 99.9% or even 99.99% and better transfer efficiency. That is to say, increasing yield and reducing cost are the solutions for mass production.

For the innovative display market, display makers are targeting foldable and flexible applications. Since Micro LED is much better than OLED in reliability, these newest applications help Micro LED become the leading technology. As Micro LED is based on semiconductor component with a strong structure which does not require protection layers or polarizer to be used in foldable solutions. For this reason, foldable display may be the new opportunity for Micro LED to enter.

Most of the production processes of Micro LED have been solved since the development started. But Micro LED technology developers continue to improve the yield of mass transfer and bonding in their efforts. Worldwide players are also developing solutions in terms of inspection and repairing in order to overcome the technology bottlenecks for Micro LED mass production.

Micro LED commercialization is still a long way to go, its revenue is anticipated to reach US$ 4.2 billion by the year 2023.

However, we still see several challenging problems in Micro LED and Mini LED production process that hinder its commercialization. so, more industry players are expected to join the market, which will help to develop solutions for technology improvements.

From the beginning of 2019, more and more companies announced their Micro LED products and their relevant patents. Some companies used PCB backplane for large size signage while many panel suppliers produced Micro LED products on glass backplanes. But the biggest size of Micro LED display module falls at 12 inches due to low yield. Basically speaking, larger sized panels are manufactured by splicing the small ones.

On the other hand, smaller sized displays usually use Si-CMOS backplane solutions whose companies from the U.S. and Europe take the lead. Apple, Facebook and Google are all working on wearable devices and AR/VR applications with Micro LEDs. Specification of related products is up to high ppi resolution with Micro LED on Si-CMOS backplane. While achieving high brightness, these products still face challenges of delivering high resolution with full color.

In the high performance display market, Micro LED only has chances for applications aiming at larger sized (above 65-inch) displays when it achieves a higher yield of 99.9% or even 99.99% and better transfer efficiency. That is to say, increasing yield and reducing cost are the solutions for mass production.

For the innovative display market, display makers are targeting foldable and flexible applications. Since Micro LED is much better than OLED in reliability, these newest applications help Micro LED become the leading technology. As Micro LED is based on semiconductor component with a strong structure which does not require protection layers or polarizer to be used in foldable solutions. For this reason, foldable display may be the new opportunity for Micro LED to enter.

Most of the production processes of Micro LED have been solved since the development started. But Micro LED technology developers continue to improve the yield of mass transfer and bonding in their efforts. Worldwide players are also developing solutions in terms of inspection and repairing in order to overcome the technology bottlenecks for Micro LED mass production.

Micro LED commercialization is still a long way to go, its revenue is anticipated to reach US$ 4.2 billion by the year 2023.