NEWS

NEWS

The important issues about aluminum PCBAs you cannot negelect before you purchase led work lamps

14-10-2022

When you make purchase plan for led work lamps, most of you will look closely at the outer housings and the lighting performance, or you may be more careful to measure their weights to make sure of 6063 aluminum housing bodies. You really did good jobs to identify the quality levels of lamps, but it is far too be enough too keep you at the ball. You forget the most important component that is hidden and easy to neglect, the inside aluminum PCBAs inside the led work lamps.

When you hear Aluminum Clad, Aluminum base, Metal Clad Printed Circuit Board (MCPCB), Insulated Metal Substrate (IMS), Thermally Conductive PCBs, etc., they are actually mean the same thing in terms of aluminum PCBA.

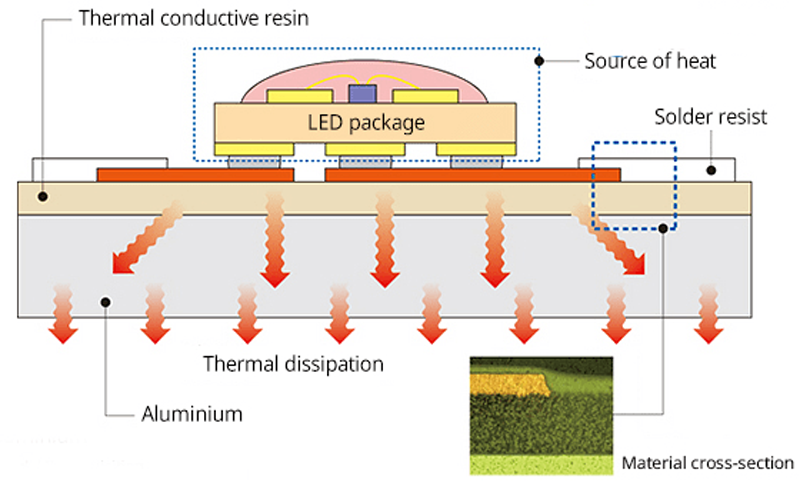

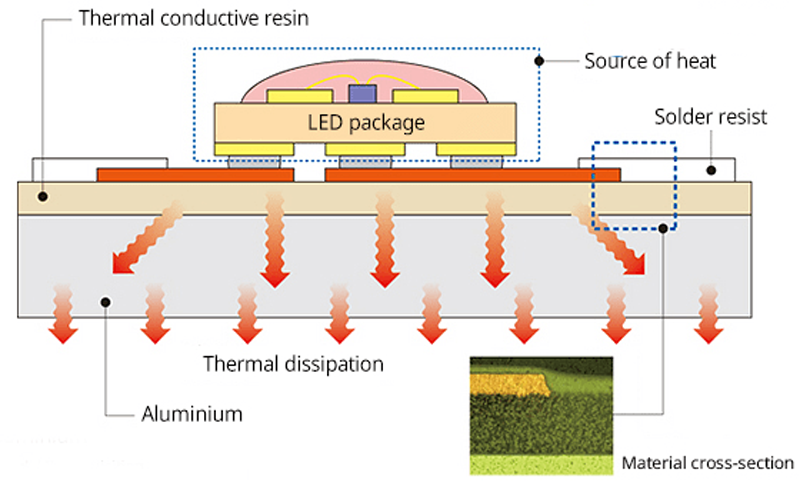

Basically, there are four basic structures for a common aluminum PCBA,such as Circuit copper layer,insulating/ dielectric layer,metal substrate,the metal base membrane layer. Basically,copper foil, diode,mos tube,IC,capacitor,inductors for EMC will be installed onto each PCBA by automatic SMT machines. In order to make sure of reliable and excellent performance, we always adopts imported Ics from Korea or Taiwan, capacitors and inductors from leading Chinese suppliers.

Basically, we make our aluminum PCBAs as thick as 1mm at least, and we adopts the thickest membrance made of aluminum alloy substrate. Depending on the degree of heat, the coating can be lower than 120 or at 250. The layer commonly has a thickness of 1mm.

In order to achieve high density luminous flux output, we adopts hightest quality China-made LED chips from Honglizhihui group or other top suppliers in China, for some of the lamps for preminum market that request super bright and long timer operations, we install expensive and imported USA-made LED chips, Taiwan or Europe-made LED chips onto inside PCBAs.

In this way, we have to consider the performance aspects of decent quality level aluminum PCBAs that play a big role for the purpose of reliable operations and illumination for long time one day.

After your engineers dismantle a led work lamp for evaluation on inside aluminum PCBAs, they need to consider the relevant issues such as thermal dissipation,thermal expansion performance,dimensional stability performance.

An aluminum substrate is more stable than the insulating substrate in the PCBA. For instance, if you heat the PCBA from 30° C to 140 - 150° C, the aluminum substrate’s dimensional change will range from 2.5 to 3.0%.

For a decent aluminum PCBAs, high quality components are just the ABC, the subsequent production workmanship is more important to decide the final quality achievement.

As we mentioned, most often, we use the thick copper foil in the PCBA.A higher standard than this, which is more than 3oz, will force you to compensate for the etching’s width requirement. Failure to do so will make the width intolerant to the etching. Therefore, we need control the etching factors carefully, compensation being a major one.

A thick copper foil in our PCB design hinders solder mask printing of aluminum PCBs. In other words, a thick layered trace copper leads the etched image to have a vast difference in the trace surface and baseboard. Thus, printing becomes difficult. A quick way to solve this problem is by using a quality solder mask oil.

Manufacturing an aluminum PCBA involves drilling mechanically, molding, and v-scoring, among others, centered on the internal via or holes. To solve these issues, electric milling and professional milling cutter are used for manufacturing products of a lower volume.

After aluminum PCBAs finish production before assembling into finished lamps, we need to put the proper storage in mind.This type of aluminum PCBA is easy to be attacting moisture, coloring to yellow or becoming black if they are not be stored in moist-free environment.

Now we come to understand that the prices of different led work lamp not only depend on the quality level of LED chips and housing but also the important and hidden PCBA inside the lamp to result in different lighting performance and reliablity in the end.

When you hear Aluminum Clad, Aluminum base, Metal Clad Printed Circuit Board (MCPCB), Insulated Metal Substrate (IMS), Thermally Conductive PCBs, etc., they are actually mean the same thing in terms of aluminum PCBA.

Basically, there are four basic structures for a common aluminum PCBA,such as Circuit copper layer,insulating/ dielectric layer,metal substrate,the metal base membrane layer. Basically,copper foil, diode,mos tube,IC,capacitor,inductors for EMC will be installed onto each PCBA by automatic SMT machines. In order to make sure of reliable and excellent performance, we always adopts imported Ics from Korea or Taiwan, capacitors and inductors from leading Chinese suppliers.

Basically, we make our aluminum PCBAs as thick as 1mm at least, and we adopts the thickest membrance made of aluminum alloy substrate. Depending on the degree of heat, the coating can be lower than 120 or at 250. The layer commonly has a thickness of 1mm.

In order to achieve high density luminous flux output, we adopts hightest quality China-made LED chips from Honglizhihui group or other top suppliers in China, for some of the lamps for preminum market that request super bright and long timer operations, we install expensive and imported USA-made LED chips, Taiwan or Europe-made LED chips onto inside PCBAs.

In this way, we have to consider the performance aspects of decent quality level aluminum PCBAs that play a big role for the purpose of reliable operations and illumination for long time one day.

After your engineers dismantle a led work lamp for evaluation on inside aluminum PCBAs, they need to consider the relevant issues such as thermal dissipation,thermal expansion performance,dimensional stability performance.

An aluminum substrate is more stable than the insulating substrate in the PCBA. For instance, if you heat the PCBA from 30° C to 140 - 150° C, the aluminum substrate’s dimensional change will range from 2.5 to 3.0%.

For a decent aluminum PCBAs, high quality components are just the ABC, the subsequent production workmanship is more important to decide the final quality achievement.

As we mentioned, most often, we use the thick copper foil in the PCBA.A higher standard than this, which is more than 3oz, will force you to compensate for the etching’s width requirement. Failure to do so will make the width intolerant to the etching. Therefore, we need control the etching factors carefully, compensation being a major one.

A thick copper foil in our PCB design hinders solder mask printing of aluminum PCBs. In other words, a thick layered trace copper leads the etched image to have a vast difference in the trace surface and baseboard. Thus, printing becomes difficult. A quick way to solve this problem is by using a quality solder mask oil.

Manufacturing an aluminum PCBA involves drilling mechanically, molding, and v-scoring, among others, centered on the internal via or holes. To solve these issues, electric milling and professional milling cutter are used for manufacturing products of a lower volume.

After aluminum PCBAs finish production before assembling into finished lamps, we need to put the proper storage in mind.This type of aluminum PCBA is easy to be attacting moisture, coloring to yellow or becoming black if they are not be stored in moist-free environment.

Now we come to understand that the prices of different led work lamp not only depend on the quality level of LED chips and housing but also the important and hidden PCBA inside the lamp to result in different lighting performance and reliablity in the end.