NEWS

NEWS

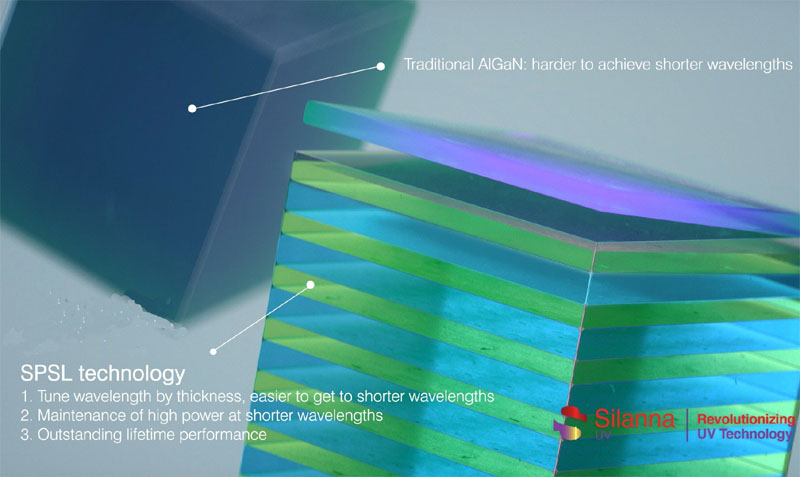

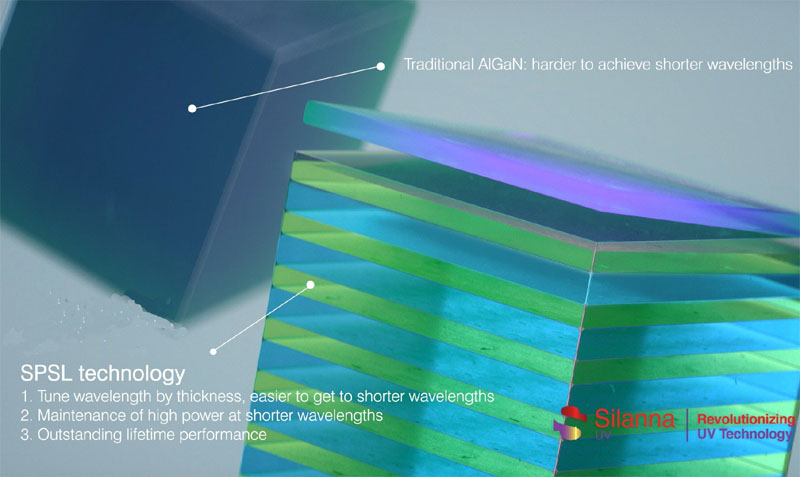

The newest SPSL technology from Silanna UV improve the performance of UVC LED below 240nm

03-12-2022

For a long time, UVC LED suppliers have adopted traditional formulas of AlGaN Aluminum Gallium Nitride alloy for the mass production of UVC LED chips. Adjusting the ratio of aluminum and gallium metal in the alloy lattice, the UVC manufactuers can turn the bandgap to achieve UV emissions from 340 nm to 210 nm to cover most of UV spectrum. However, actually, emission below 260nm need high Al-content AlGaN, which is very hard to achieve needed n and p-type doping resulting in poor electrical performance.High-Al content AlGaN also suffers from UV light extraction because of polarization of emitted light in the far UV spectrum range below 240nm.

After years of developments, Australia-based Silanna UV launches a newest short period superlattic technology(SPSL) to solve the above-mentioned problems. In doing so, they carefully build up alternating several hundred layers of AlN and GaN to create a so-called SPSL. The key properties of bandgap and conductivity can be tuned very well by adjusting the thickness of relevant layers.That is to say, the problems resuting from High-Al content AlGaN are solved in some degrees so as to avert the issues of poor electrical characteristics and light losses.

Based on the newest SPSL technology, these new UVC LEDs from Silanna UV are the perfect solution for various deep UV and far UV use cases such as sterilization, water and gas sensing, and instrumentation applications.

After years of developments, Australia-based Silanna UV launches a newest short period superlattic technology(SPSL) to solve the above-mentioned problems. In doing so, they carefully build up alternating several hundred layers of AlN and GaN to create a so-called SPSL. The key properties of bandgap and conductivity can be tuned very well by adjusting the thickness of relevant layers.That is to say, the problems resuting from High-Al content AlGaN are solved in some degrees so as to avert the issues of poor electrical characteristics and light losses.

Based on the newest SPSL technology, these new UVC LEDs from Silanna UV are the perfect solution for various deep UV and far UV use cases such as sterilization, water and gas sensing, and instrumentation applications.